NAVCO Expands Manufacturing Space for Growth

NAVCO (National Air Vibrator Company) has completed a major building project at its Houston, Texas headquarters to expand its bin hopper vibrator, railcar vibrator, and vibratory equipment manufacturing quality control and testing space, and to build out additional, new office space for its growing engineering staff.

“While some manufacturers paused during the pandemic, NAVCO moved full speed ahead by expanding our facilities for growth in 2022 and beyond,” NAVCO president Geoff Neundorfer said.

The expansion space provides two distinct areas for growth:

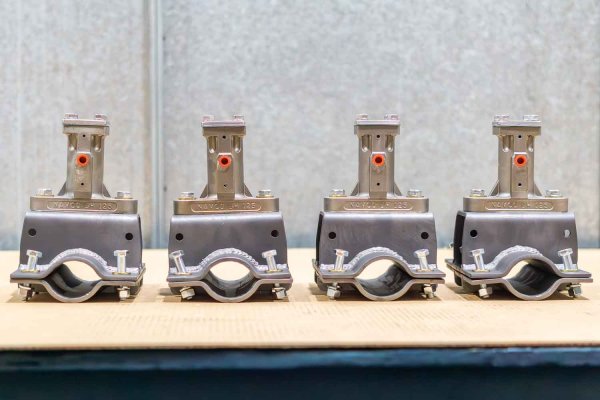

The quality control and testing team now has greater through-put to run more tests faster on bin hopper vibrators, railcar vibrators, and other industrial vibratory equipment. The bulk materials handling lab measures qualities such as compaction, flow, feeding, conveying, and sizing, using applied vibration technology.

The growing engineering department has expanded square footage for enhanced computer technology systems and more spacious workspaces. A new panel shop will accelerate development of controls to enhance process integration of industrial vibrators and vibrating equipment.

For more information, contact Geoff Neundorfer at +1 (832) 467-3636. Or find us on LinkedIn.

ABOUT NAVCO

NAVCO (National Air Vibrator Company) was founded in 1955 to design and manufacture industrial vibratory equipment needed to power the post-war industrial boom in the USA and North America. NAVCO bin hopper vibrators, railcar vibrators, and other vibratory equipment are used in rail cars, trucking, foundries, and process manufacturing, to facilitate flow of bulk materials through hoppers, bins, bunkers, and other vessels for efficiency and profitability.

NAVCO has become a leading expert in material flow solutions. NAVCO has continually expanded its product line, and now designs and manufactures specialized vibratory flow systems, such as vibrating tables, portable rail car vibrators, and small, adaptable vibratory devices. NAVCO industrial vibratory equipment has been implemented in manufacturing processes across Agriculture, Energy, Construction, Mining, Metal Manufacturing, Pharmaceuticals, Food Processing and many other industries.