Recent News

Railside Railcar Shaker Improves Unloading in Aggregate Yard

Unloading railcars at an aggregate yard is a crucial first step in the process for preparing material for loadout. How quickly and efficiently each railcar is unloaded has a significant impact on the productivity of the yard. When aggregates are brought in by rail, they often arrive in quantities of around 100 railcars at a […]

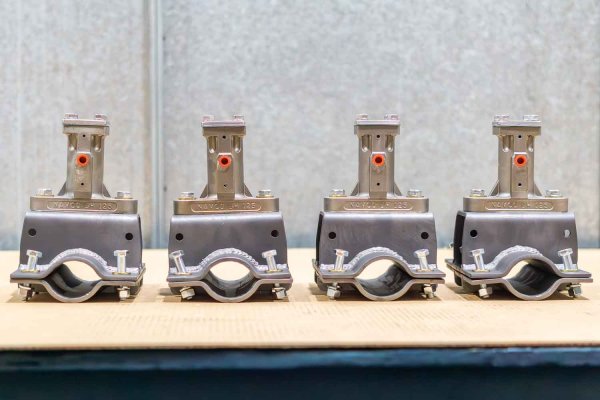

Read MoreFoundry Vibrators Help Produce High Quality Cores in a Foundry

NAVCO was approached by a customer for help with improving their molding core process at their automotive parts foundry. When casting automotive parts, ensuring the final product is of the highest quality possible is a primary objective. One of the key steps in achieving a high-quality final product lies in the mold cores. During production […]

Read MoreStainless Steel Pipe and Chute Vibrators Improve Material Flow

NAVCO had a customer approach us for help in addressing an issue with material plugging at their pharmaceutical production facility. The product has a tendency to stick or clump together and builds up in the pneumatic conveying system as it is moved through the facility. This build up results in reduced flow and eventually leads […]

Read MoreVibrahoist Improves the Hot Dip Galvanizing Process

Galvanizing metal is one of the best ways to ensure a piece of steel is able to provide a long productive working life, even in harsh environments. The hot-dip galvanizing process is the go to method for galvanizing a wide variety of products. Through working with galvanizing facilities over the years, NAVCO developed the Vibrahoist […]

Read MoreStainless Steel BH Vibrators Help Spice Up Dinner

Not getting the correct blend of spices on a dish can take a great meal and make it mediocre. This is why food producers work hard to come up with the exact measurements of spices for their recipes and work to ensure all the food they produce meets their expectation and their customer’s. One of […]

Read MorePipe Vibrators Solve Material Flow Issues in Power Plant

Pipes and chutes are used in many industries to move material quickly and efficiently within the facility or plant. While these are often the best solution for moving material between areas of the process, they can be a primary source of material flow constraints, such as plugging. Conventional techniques to restore flow, like hitting the […]

Read MoreBH Truck Vibrators Improve Dump Truck and Trailer Unloading

Dump truck and trailer unloading can go from an easy job to a time consuming one, depending on the material the truck is hauling and the weather conditions. In the past, truck drivers have come up with ways to deal with sticking material by swinging sledge hammers and “bouncing” the truck in an effort to […]

Read MoreNAVCO Expands Manufacturing Space for Growth

NAVCO (National Air Vibrator Company) has completed a major building project at its Houston, Texas headquarters to expand its bin hopper vibrator, railcar vibrator, and vibratory equipment manufacturing quality control and testing space, and to build out additional, new office space for its growing engineering staff. “While some manufacturers paused during the pandemic, NAVCO moved […]

Read MoreRailcar Unloading: Eliminate Costly Carryback

A significant contributor to high costs of materials that are transported by railcar is often the material that remains in the railcar after the unloading process is complete. The residual material, known as carryback, increases operational costs as material is billed based on the weight loaded at time of shipment. This means any material remaining […]

Read MoreVacuVibe Improves Bulk Material Densification in Carbide Facility

Many industries struggle to meet their target weight/ fill levels in bulk material containers. Material not densifying enough within its container during the loading process can create costly delays, reduced margins, higher shipping costs, and constrain plant capacity. To combat these costly inefficiencies many operators resort to unsafe and destructive practices, such as hammering or […]

Read More