Top 3 Advantages of Extreme Duty BH Vibrators vs Air Cannons

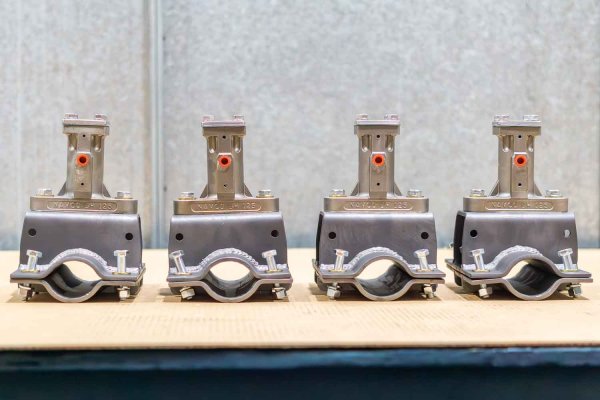

Extreme Duty BH Vibrators and Air Cannons (Blasters) are both used to promote material flow in heavy walled vessels such as bunker and chutes. Extreme Duty BH Vibrators are large pneumatic piston vibrators that utilize vibration to promote flow, whereas air cannons utilize high volume, high pressure bursts of air. While both types of equipment are designed to solve material flow issues caused by rat holing and bridging (arching), Extreme Duty BH Vibrators provide three distinct advantages over air cannons, larger area of material influence, simpler installation, and increased safety.

Larger Area of Material Influence

Extreme Duty BH Vibrators transmit energy efficiently through the bunker wall and into the bulk material. Energy produced by the vibrators propagates through the hopper wall, influencing material over a large area. This vibrational influence reduces the sliding friction of the wall and the material’s cohesive strength – two key material characteristics related to improving flow. By influencing a large area of material, the number of vibrators required for a given vessel is reduced.

VS.

Air Cannons direct a concentrated, high pressure burst of air into the bunker. The bursts effectiveness is limited to the material directly in its path as the air dissipates quickly and is not transmitted efficiently throughout the bunker. This limitation means that many more air cannons are required to influence material over the same area as just a one BH Vibrator.

Simpler Installation

Extreme Duty BH Vibrators are installed on the exterior of the bunker. They are available with match drilled mounting plates that simply weld to the exterior bunker wall. The vibrator is then bolted to the mounting plate, this installation method eliminates the cutting and drilling of the bunker wall that is required for installation of air cannons. Cutting and welding compromises the integrity of the vessel, and introduces new flow obstructions to the inside wall. In most cases the bunker doesn’t have to be emptied for installation of the Extreme Duty BH Vibrator, removing a time consuming and costly process.

VS.

Air Cannon installation requires the bunker wall to be drilled or cut to install the blaster nozzle inside the bunker. Additional access holes are also needed to attach the nozzle inside the bunker. Because of the need to access the interior of the bunker it must first be emptied and cleaned prior to the installation. Each additional hole cut into the bunker is another potential impediment to the material that fills the bunker.

Increased Safety

Extreme Duty BH Vibrators have excellent bunker cleanout characteristics, effectively removing stagnant pockets of material on the bunker walls. This material, if left, can cause corrosion and, in some cases becomes a combustion hazard. By removing the stagnant material, the vibrator eliminates the need for manual cleanouts and reduces employee risk by ensuring the bunker is empty for internal inspections.

VS.

Air Cannons operate by introducing a blast of high-pressure air into the bunker. This influx of oxidant can be a safety hazard in applications involving combustible material, such as coal. Also, inefficient cleanout of bunkers may lead operating personnel to hammering the hopper. This manual hammering threatens the safety of the operator and causes damage to the hopper.

The NAVCO Extreme Duty BH Vibrators influence more material, are simpler to install, and keep the workplace safer when compared to Air Cannons. If you are dealing with material flow problems in large, heavy walled bunkers, then NAVCO Extreme Duty BH Vibrators are your solution.

You can learn more about the Extreme Duty BH Vibrator here and you can Contact Us Today with any questions about material flow problems you’re facing. NAVCO has over 65 years of experience providing applied vibration solutions to the challenges of keeping bulk material moving.