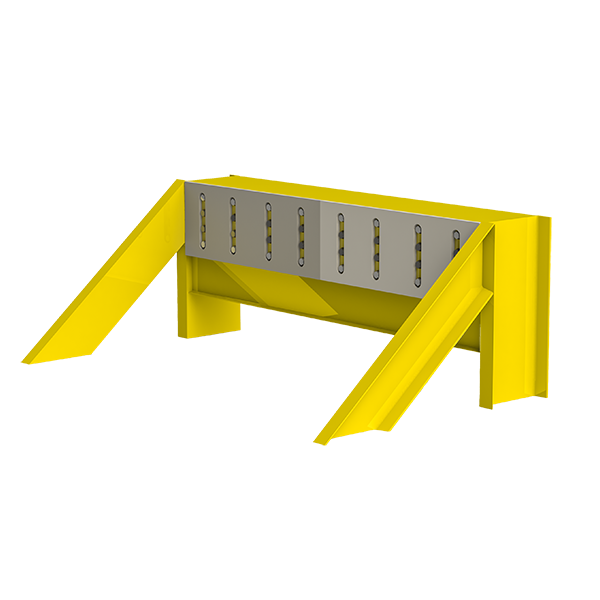

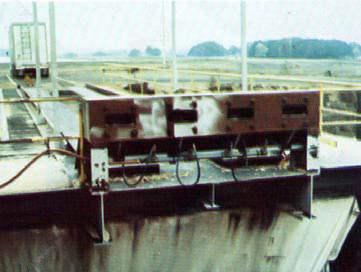

The Truck Dumper Shaker from NAVCO® aids in the efficient unloading of bulk materials from trucks and trailers unloaded using truck dumpers. Incorporated into the stop/bumper, the truck dumper shaker utilizes pneumatic piston vibrators to loosen packed material and promote continuous flow.

Truck Dumper Shaker

Truck Dumper Shaker Improves

Truck Dumper System Unloading Times

Heavy-Duty Truck Dumper Shaker, Made in the USA

Made in the USA, the NAVCO Truck Dumper Shaker is designed and manufactured in Houston, TX.

Long, Productive Operating Life

Designed to integrate with existing truck dumper systems, the Truck Dumper Shaker is designed with a heavy steel construction and minimal moving parts. This simple design provides a long, reliable operating life in the toughest conditions.

Working Across Many Industries

Aggregates, Power, Mining, Pulp & Paper, Wood, Agriculture, Food, and more.

Materials

Processed Wood, Bioenergy, Pulp & Paper, Particle Board, Potatoes, Onions, Fruits, Vegetables, and more.

A Safer, Faster Truck Dumper Unloading System

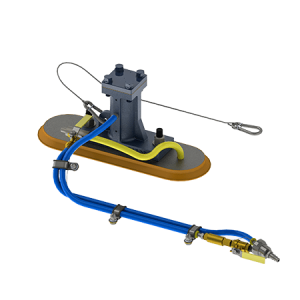

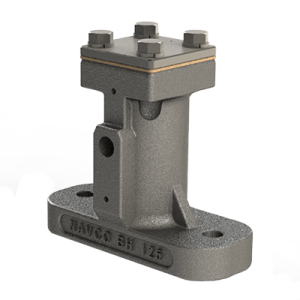

Pneumatic Vibration

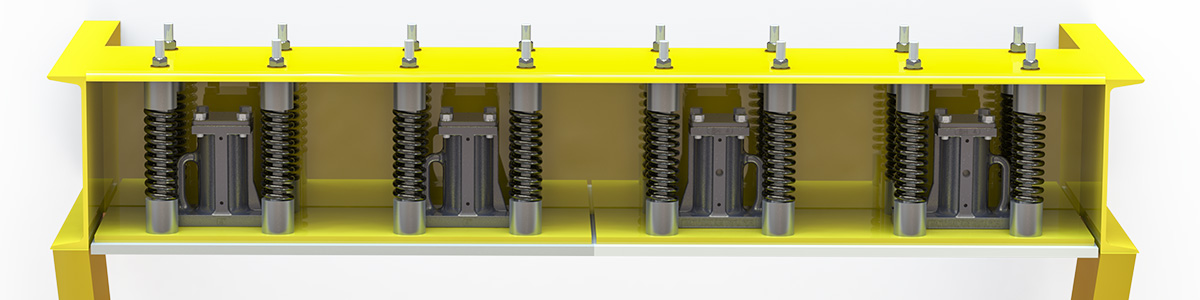

Four NAVCO BH 4 long stroke impacting vibrators operate simultaneously to loosen packed material and allow continuous free flow. See above top down cut away image.

No More Jolting

Jolting truck dumpers puts extra wear and tear on the dumper that can lead to pre-mature equipment failure and expensive repairs. The Truck Dumper Shaker is designed to efficiently transmit its vibrational forces into the trailer, while also isolating itself from the rest of the truck dumper system. This system ensures the energy is directed where it is needed, providing the benefits of jolting without the wear and tear.

Reduce Manual Unloading

The truck dumper shaker automates the process of releasing stuck material in trailers. This greatly reduces the need for personnel to enter the trailers and manually sweep out the remaining material.

Improve Safety

Safety of personnel is improved by reducing the need for the repetitive and laborious task of manually sweeping out trailers to ensure all the material is collected.