NAVCO® Molding Core Vibrators are high frequency pneumatic piston vibrators. These heavy duty vibrators offer long service life and ensure rapid, efficient core drawing and smooth surface finish of castings in foundry roll over molding machines.

Molding Core Vibrator

Industrial Vibrators

Built for Foundry Molding Core Machines

Foundry Vibrators, Made in the USA

Made in the USA, Molding Core Vibrators are manufactured in a state of the art manufacturing facility with checks at critical steps to assure the highest quality available.

Long Productive Operating Life

Designed with minimal moving parts, these vibrators provide a long, reliable operating life in the harshest of conditions.

Higher Density Molds with Smoother Finishes

Adding vibration to the mold core process creates a higher density mold which in turn creates smoother finishes on the final product.

Pneumatic (Air) Power to Fit Your Work Flow

Molding Core Vibrator are pneumatic / air vibrators that operate at a low air consumption level and are easily incorporated into existing machines.

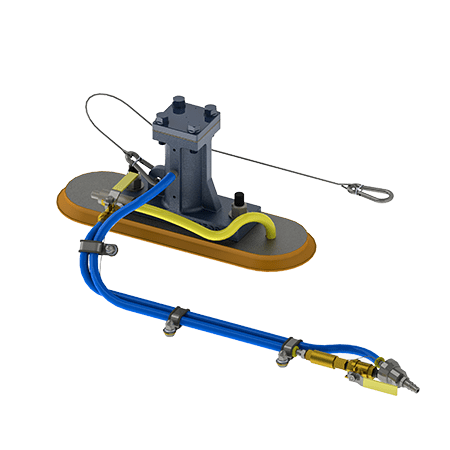

Sinto Roll Over Molding Core Machine

With models designed specifically for Sinto Roll Over Molding Core Machines the molding core vibrator provides a reliable, non-marking way of releasing the core, producing a higher quality final product.

Hunter Roll Over Molding Core Machines

Precision designed models are available for placement in special Hunter vibrator holding arm, with custom-placed exhaust ports in the head section and two direction, high frequency piston action. (Two vibrators are used on each machine)

Herman Roll Over Molding Machines

Precision designed models are available for Herman-type molding machines with no body assembly bolts to shear, fatigue or stretch.

Have a Question? NAVCO Can Help

NAVCO has a team of experts with the knowledge and experience to help find the right applied vibration solution for your application.

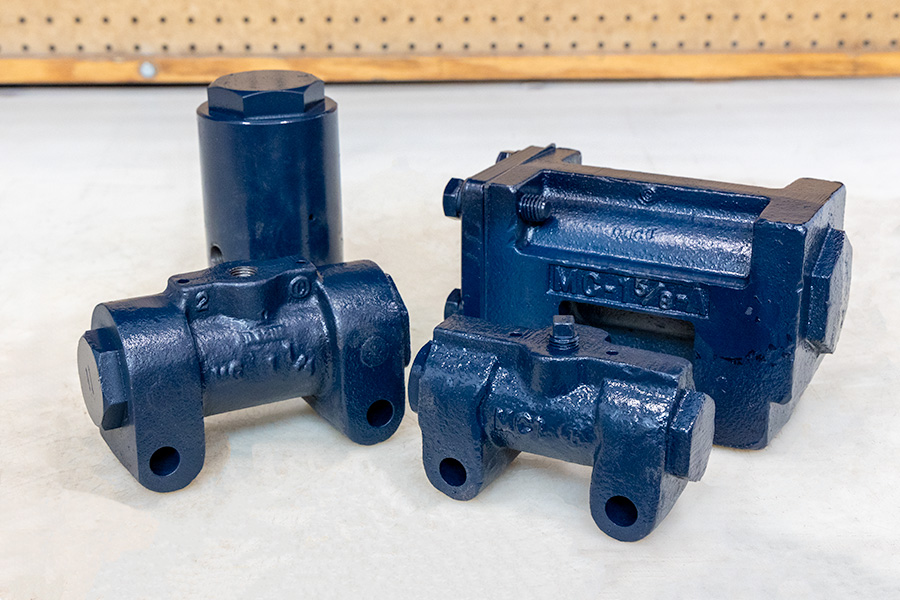

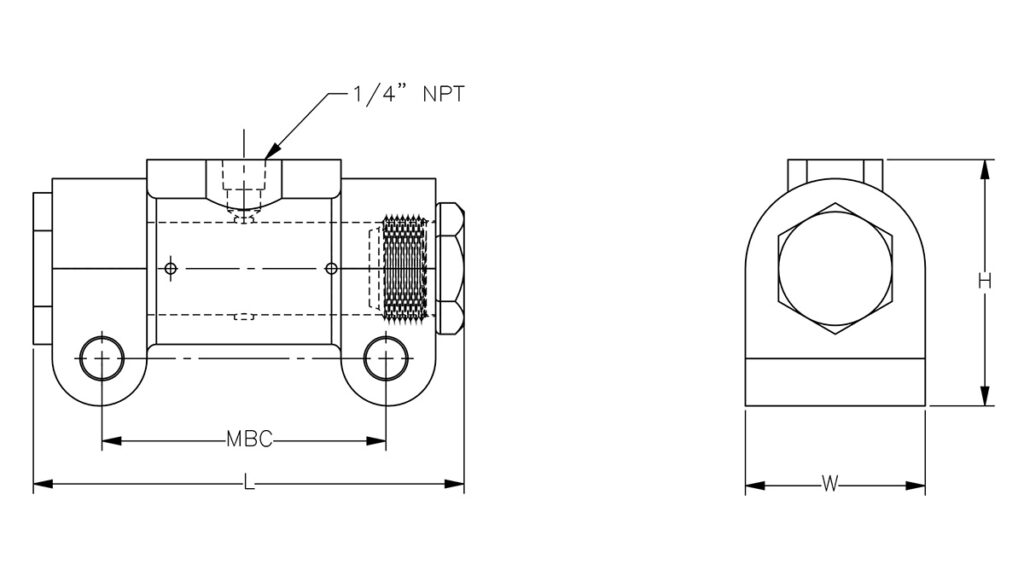

Multiple Sizes to Fit Your Molding Core Machine

Model | L | W | H | Mounting Bolt Centers* | Wt. - lbs |

MC 1.00 | 5" | 2" | 2-3/4" | 2-7/8" or 3" | 4 |

MC 1.25 | 5-3/4" | 2-3/8" | 3-1/4" | 3-3/4" or 4" | 7 |

MC 1.62 | 7" | 3-1/4" | 4-1/4" | 4" | 16 |

* MC 1.00 & MC 1.25 are available with optional bolt centers to fit a variety of diffrent machines. | |||||

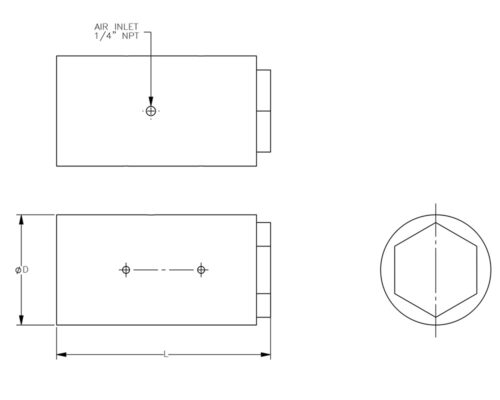

Model | L | D | Wt. - lbs |

SMC 1.62 | 5-3/4" | 2-15/16" | 9 |

SMC 1.62 Hunter | 5.700" | 2-15/16" | 8-3/4 |