Ship more bulk materials. Separate more parts. Test more products.

NAVCO® vibrating tables enable you to Get More Done!

Vibrating Tables

Shake Your Way to More Results

With NAVCO Vibrating Tables

Utilized Across Multiple Industries

Our tables are utilized across a wide range of industries. Including Agriculture, Energy, Construction, Pharmaceutical, Mining, Food Processing, Metal Manufacturing, and many more.

Power Options to Fit Your Work Flow

Available with electric or pneumatic drives. Allowing for easy integration into your production line.

Reliable, Field-Proven Industrial Design

Designed with minimal moving parts. Ensuring a long reliable operating life.

A Table for Every Container

NAVCO Vibrating Tables can be customized to handle a wide range of material containers including: Bulk Bags, Boxes, Drums (55, 30, and 15 gallon), Pipes, Tubes, Sheets, Intermediate Bulk Containers (IBCs), Cartons, Housings, and many more.

Vibration Tables That Enhance

Your Products & Work Flow

Through the use of vibration, our tables automate labor intensive processes. This enables you to increase productivity and enhance the quality of your products.

Compaction Table

Increase the amount your containers hold. Decrease your shipping costs by maximizing load sizes.

Settling Table

Prevent peaks from building and slowing production by flattening material as it’s loaded.

De-Aerating Table

Enhance product quality. De-aerate concrete molds and other cast materials, giving them improved structural integrity and quality.

Shakeout Table

Remove sand and debris from castings in your foundry’s processes.

Jolt Table

Ideal for densification of powdered metal materials into molds, or densifying light fluffy materials that do not respond well to other types of vibration.

Testing & Quality Assurance Table

Used for product quality and fatigue testing. Our vibrating tables ensure your products meet your customer’s expectations.

and More...

NAVCO vibrating tables can be customized to handle other non-traditional applications. Contact Us to discuss your unique vibrating table application.

Good Vibrations

Applying too much or too little vibrational force or frequency can lead to loss of material or even damaged products. NAVCO fine-tunes the force and frequency output of our vibrating tables to your exact application.

Repeatable Quality

Whether it’s making sure an ice cream tub is filled to the top or making sure the powdered material in a mold is the appropriate density, our vibrating tables take the guesswork out of making sure your product is the same every time.

Our Tables Are Endlessly Customizable

In-house engineering and design teams provide customized vibration tables to meet your exact needs, making them easily integrated into your current work flow.

Production Team Player

Need to add a vibration table into your production line? NAVCO can build custom tables from the ground up. Our team of engineers will work closely with you to design a table that fits seamlessly into your process. This allows for reduced downtime and installation costs.

Application Specific Customization

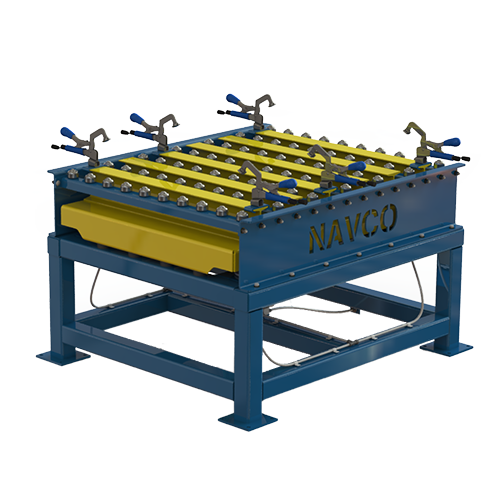

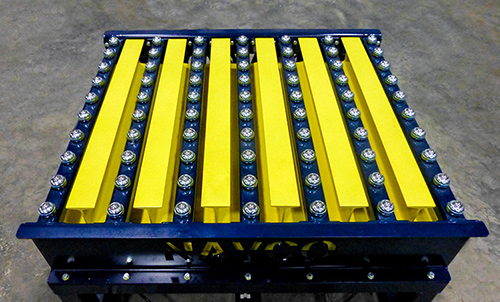

Our engineers work with you to provide the application specific customizations needed to get the job done. These customizations include grid tops, loads cells, scales, containment rails, clamps, and more.

Electromechanical drive, custom adjustable fixturing for securing various sized loads.

Pneumatic drive, roller grid top vibratory table with easy lift rollers for quick clean between grids.

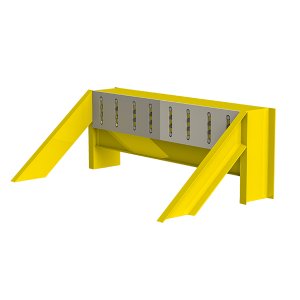

Pneumatic drive, hopper top vibratory table with removable/replaceable screen top.

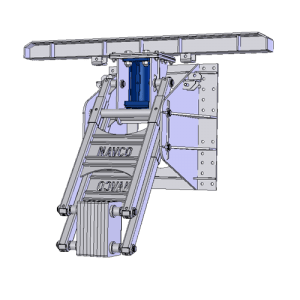

Dual electromechanical drive, roller grid top vibratory table with scissor lift for height positioning.

Tables that Rise to the Occasion

Need to move the table during process change overs? NAVCO can provide tables that move in and out of position to allow for material to move along the production process unimpeded. Our tables can provide the vibration you need, while keeping your productivity high.

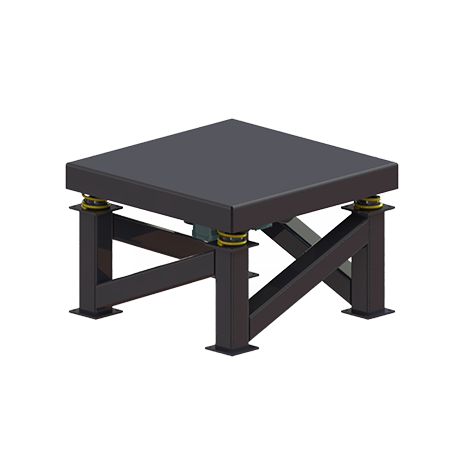

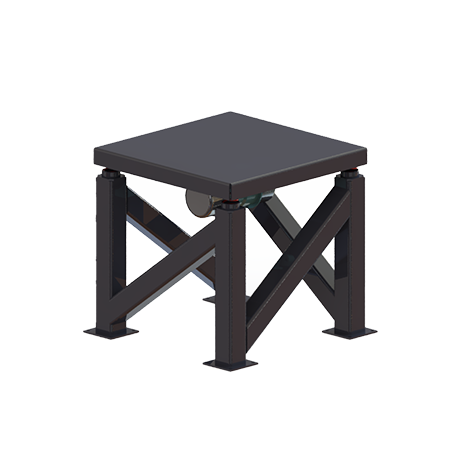

Standard Vibrating Tables

Get You Up and Running Fast

Available in 48”, 36”, & 24” square sizes. Our standard vibrating tables are available with short lead times, allowing your project to get up and running fast!

48″ Square Vibrating Table

36″ Square Vibrating Table

24″ Square Vibrating Table