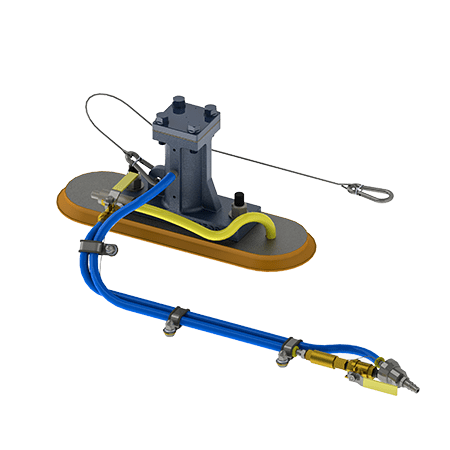

NAVCO Ball Vibrators are pneumatically driven rotary vibrators engineered to keep your material flowing no matter where it’s housed. Whether it’s material sticking, bridging or rat holing, NAVCO Ball Vibrators break up the log jam and Get Your Material Moving!

Ball Vibrator

Industrial Ball Vibrators

High Frequency Vibration for

Densification and Material Flow

Time Tested Industrial Ball Vibrators, Made in the USA

Made in the USA. NAVCO’s pneumatic Ball Vibrators work daily to keep material flowing and processes going all across the US and the world.

Supporting Multiple Industries

Construction, Concrete, Chemical, Agriculture, Pharmaceutical, Mining, Food Processing, and many more.

Pneumatic (Air) Power to Fit Your Work Flow

Pneumatically driven Ball Vibrators are easily incorporated into existing industrial processes.

Non-Impacting, High Frequency Low Amplitude Vibration

Ball Vibrators operate by using compressed air to drive a bearing grade steel ball around a hardened raceway ring within the vibrator, creating a non-impacting high frequency, low amplitude vibration.

Improved Concrete Molds and Forms

Ball Vibrator’s high frequency vibration helps to release entrapped air and settle concrete. This ensures an even density and smooth finish in the final product.

Improve Material Flow

Ball Vibrators have been utilized on all the most common containers used in industry, including Silos, Hoppers, Bins, Bunkers, Chutes, Pipes, Vessels and International Bulk Containers (IBC).

Have a Question? NAVCO Can Help

NAVCO has a team of experts with the knowledge and experience to help find the right applied vibration solution for your application.

Multiple Sizes to Fit Your Application

NAVCO BALL Vibrators are available in 4 models in multiple sizes:

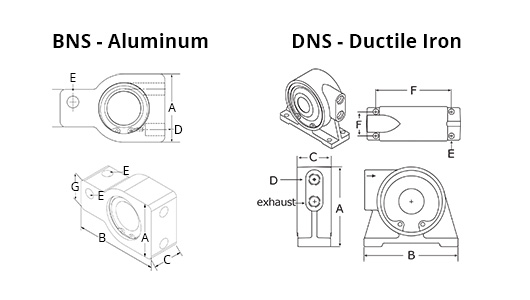

BNS – single bolt mount inlet and exhaust ports on one end

DNS – four bolt mount – inlet and exhaust ports on side of unit – air travels in a “C” shape.

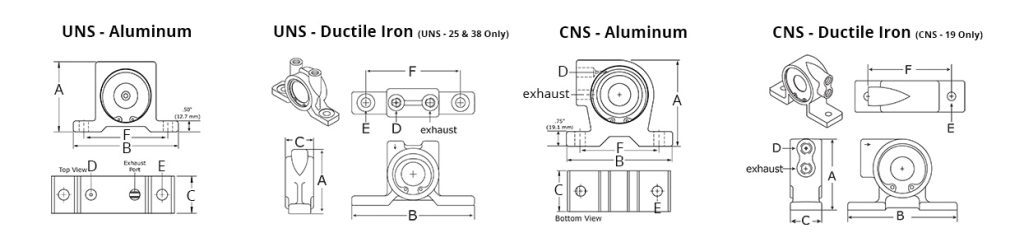

CNS – two bolt mount – inlet and exhaust ports on side of unit – air travels in a “C” shape.

UNS – two bolt mount- inlet and exhaust ports on top of unit – air travels in a “U” shape.

Model | A | B | C | D (NPT) | E | F | G | Weight |

in | in | in | in | in | in | in | lb | |

BNS - 10 | 2.0 | 3.1 | 1.1 | 1/8 | 11/32 | Single Bolt | 1.1 | 0.5 |

BNS - 13 | 2.0 | 3.1 | 1.1 | 1/8 | 11/32 | Single Bolt | 1.1 | 0.5 |

BNS - 16 | 2.6 | 4.0 | 1.3 | 1/4 | 7/16 | Single Bolt | 1.4 | 1.0 |

BNS - 19 | 3.1 | 4.4 | 1.5 | 1/4 | 7/16 | Single Bolt | 1.5 | 1.5 |

BNS - 25 | 3.8 | 5.3 | 1.8 | 1/4 | 7/16 | Single Bolt | 1.7 | 2.6 |

DNS - 41 | 5.7 | 6.8 | 2.5 | 1/2 | 2/5 | 5.50 x 1.75 | N/A | 10.5 |

DNS - 51 | 5.7 | 6.8 | 2.5 | 1/2 | 2/5 | 5.50 x 1.75 | N/A | 11.0 |

Model | A | B | C | D (NPT) | E | F | G | Weight |

in | in | in | in | in | in | in | lb | |

CNS - 19 | 3.4 | 5.3 | 1.5 | 1/4 | 7/16 | 4.00 | N/A | 2.4 |

CNS - 25 | 4.4 | 5.4 | 2.1 | 1/4 | 17/32 | 4.00 | N/A | 3.3 |

CNS - 35 | 4.4 | 5.4 | 2.1 | 1/4 | 17/32 | 4.00 | N/A | 3.5 |

UNS - 13 | 2.6 | 5.0 | 1.2 | 1/8 | 11/32 | 4.00 | N/A | 0.8 |

UNS - 19 | 3.2 | 5.0 | 1.5 | 1/4 | 7/16 | 4.00 | N/A | 1.4 |

UNS - 25 | 3.9 | 6.5 | 1.8 | 1/4 | 7/16 | 5.00 | N/A | 3.5 |

UNS - 38 | 5.2 | 7.8 | 2.3 | 3/8 | 7/16 | 6.00 | N/A | 8.0 |