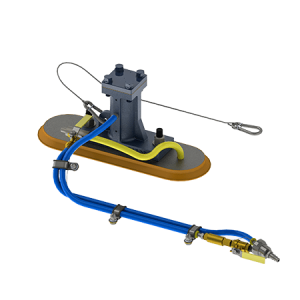

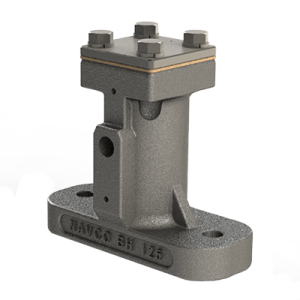

The BH Truck Vibrator from NAVCO aids in the efficient unloading and loading of dry bulk material in the trucking industry. These pneumatic piston vibrators can be welded to a truck bed / body or hopper bottom trailer to increase material flow when unloading or increase load size when loading. NAVCO BH Truck Vibrators promote continuous and reliable flow in a wide range of trucking applications.

BH Truck Vibrator

A Powerful Truck Vibrator

For Quicker, Complete Bulk Material Unloading

Built in the USA

Made in the USA, the NAVCO BH Truck Vibrator is designed and manufactured in Houston, TX.

Utilized on a Wide Range of Trucks

BH Truck Vibrators improve bulk material flow on a wide range of trucks including:

- Dump Trucks

- Volumetric Mixer and Gunite Trucks

- Hopper Bottom Trailers

- Salt Trucks

- Garbage Trucks

- Fertilizer and Seed Tender Trucks

- Spreader Trucks

- Cement Pump Trucks

- Frac Sand Pneumatic Transport Trailers

- And more

Complete Unloading

Stubborn material that sometimes remains in the hopper or bed is more easily and completely removed, eliminating “dead” cargo.

Pneumatically Driven Truck Vibrator

BH Truck Vibrator is designed to run completely on air making it ideal for incorporating into your truck’s current air compressor.

Help Extend Vehicle Operating Life

Complete unloading without tailgate banging, lift bouncing, braking, or jerking means longer life for the truck and equipment.

Got a Question?

NAVCO has a team of experts with the knowledge and experience to help get your bulk material flowing.

Safe Truck Unloading

Protect Workers and Equipment

Eliminate the need to hit potential injury causing sledge hammers against your truck to initiate material flow. The BH Truck Vibrator produces vibration powerful enough to break up material bridging and rat holes, while leaving trucks damage free.

Clean Out

Ensure a more thorough and complete cleanout process without the hassle or danger of swinging hammers or climbing into the truck bed or trailer. The BH Truck Vibrator will help to remove long standing material that, if left, can cause corrosion and in some instances becomes a combustion hazard.

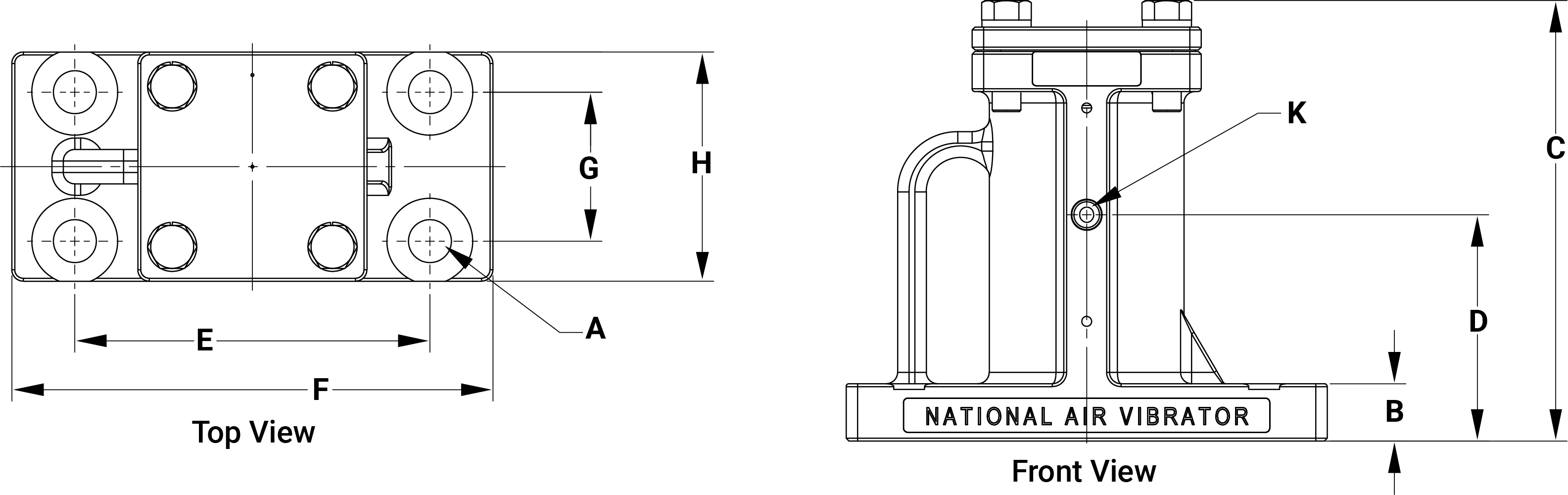

Specifications and Dimensions

Model* | A (1) | B | C | D | E | F | G (2) | H | J | K - NPT (3) | Wt. - lbs | Wall Thickness |

5/8 | 1 | 7-1/4 | 3-3/4 | 7-1/2 | 9 | N/A | 3-1/4 | 1/4 | 1/4 | 18 | 3/16 – 1/4 | |

7/8 | 1-3/8 | 9-1/2 | 5 | 7-3/4 | 10-1/2 | 3-1/4 | 5 | 3/8 | 3/8 | 50 | 1/4 – 3/8 | |

7/8 | 1-1/2 | 12 | 6-1/4 | 7-3/4 | 10-1/2 | 3-1/4 | 5 | 3/8 | 3/8 | 64 | 1/4 – 3/8 | |

1 | 1-1/4 | 11-3/4 | 5-7/8 | 12 | 14-1/2 | 4 | 6-1/2 | 1/2 | 1/2 | 105 | 3/8 – 1/2 | |

* Click Model to View Product Data Sheet (PDF) (1) Mounting Bolt Diameter (2) N/A Indiscates Two Bolt Mount (3) Single Impact Model NPT Size Found on Product Data Sheet | ||||||||||||